AS Series Shaft Locating Washers for Cylindrical and Needle Thrust Bearing

Overview Package size per unit product 38.00cm * 55.00cm * 3.00cm Gross weight per unit product 0.010kg Product Descript

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | AS 3552 |

| Lubrication | Light Grease or Oil |

| Features | Matching Bearing AXK-3552 |

| Transport Package | Industrial Packing/Customized |

| Specification | 35x52x1 |

| Trademark | GIL or Customized |

| Origin | China |

| HS Code | 8482102000 |

Packaging & Delivery

Package size per unit product 38.00cm * 55.00cm * 3.00cm Gross weight per unit product 0.010kgProduct Description

Product Description

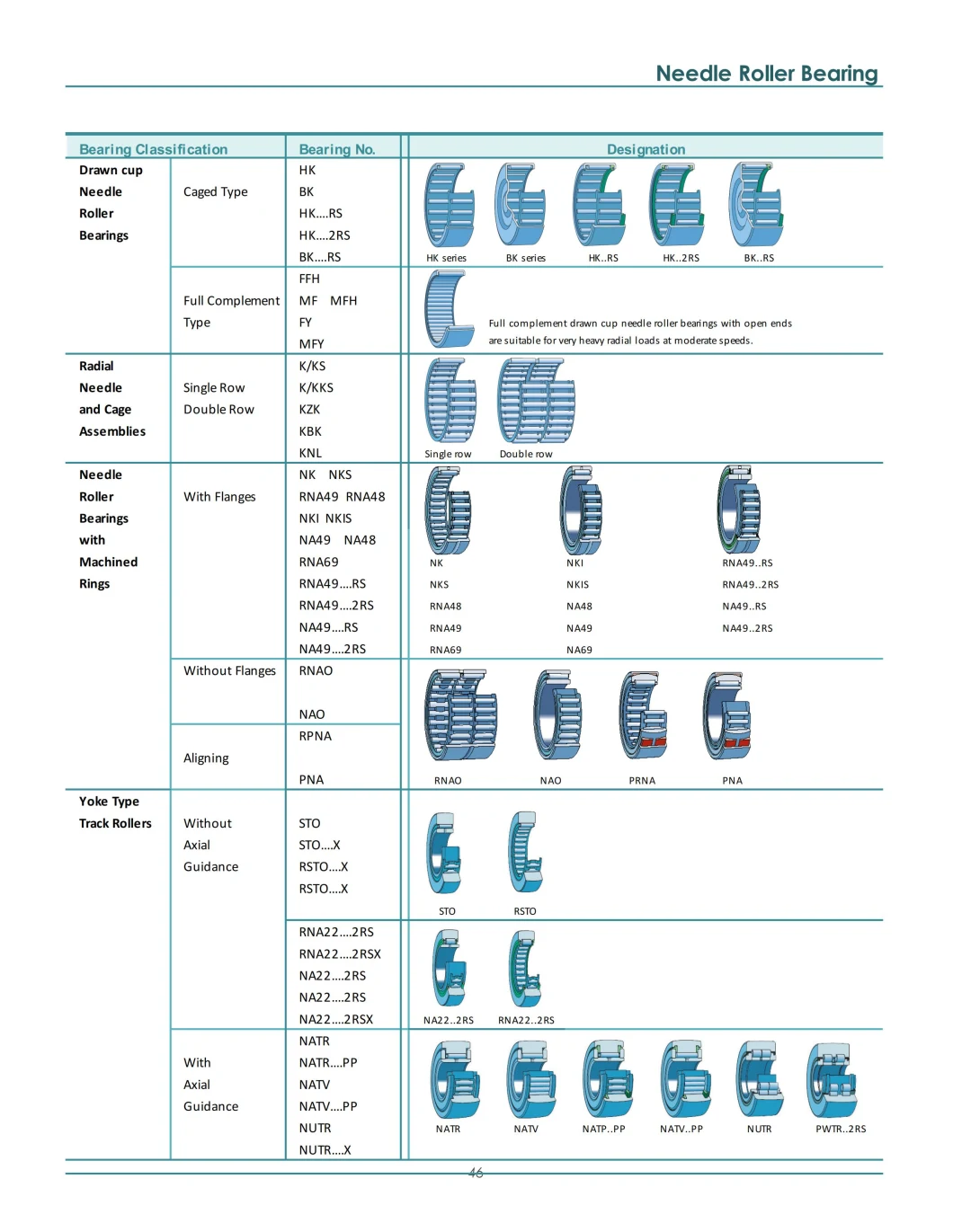

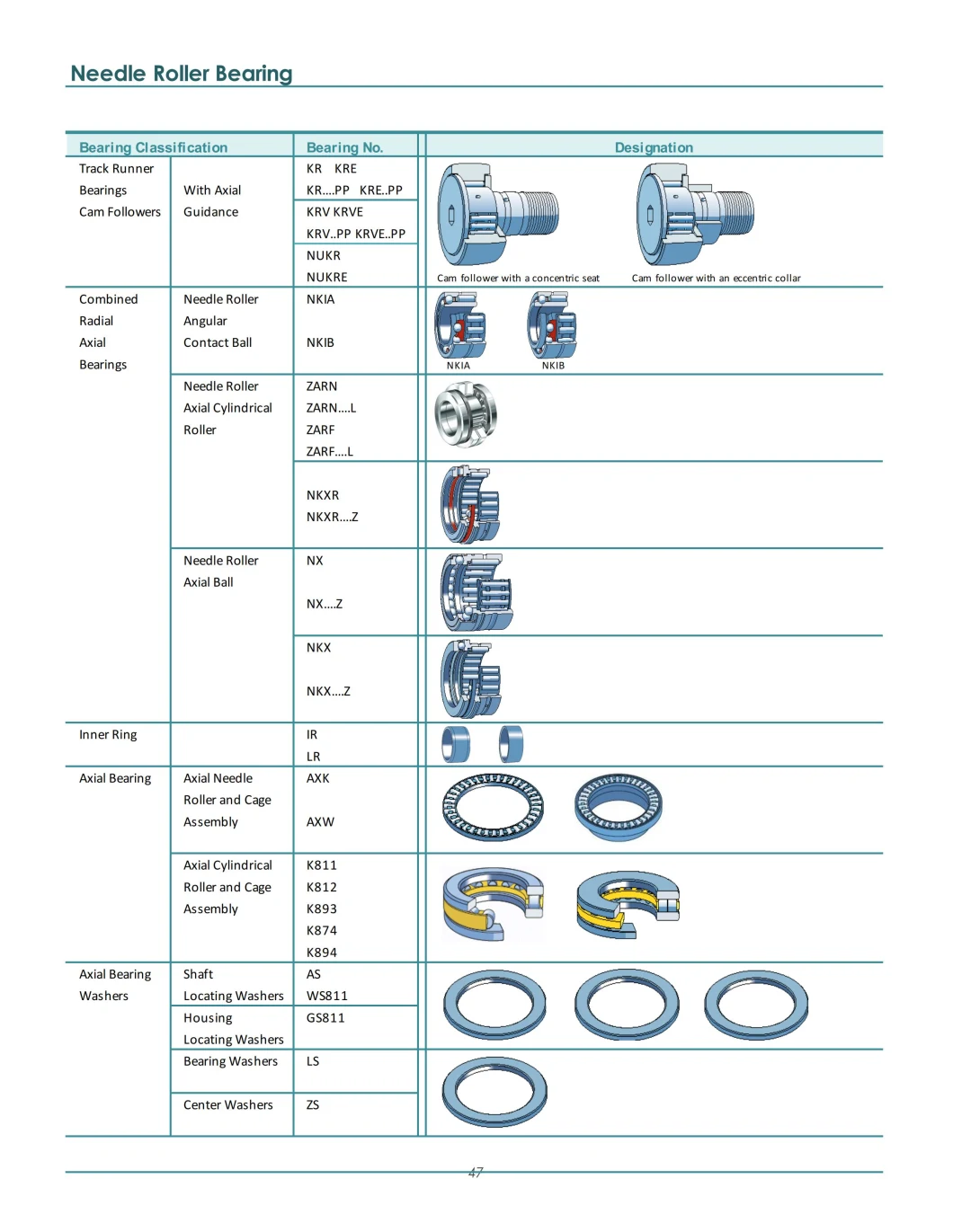

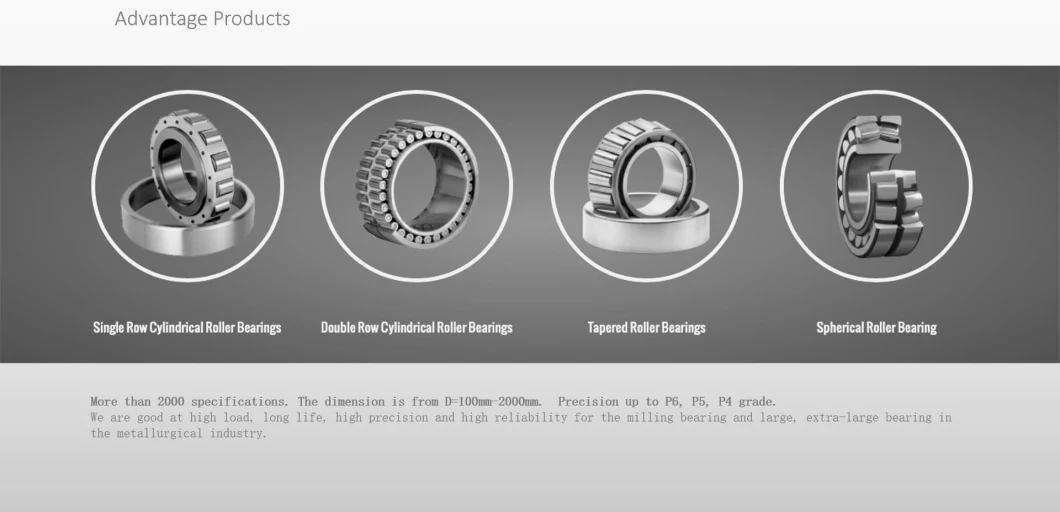

Roller Bearings01

| Cylindrical Roller Bearings | Spherical Roller Bearings |

| Taper Roller Bearings | Needle Roller Bearings |

02Applications:

| Agriculture | Construction |

| Cars and light trucks | Industrial transmission |

| Metals | Mining & mineral processing |

| Industrial fans | Marine |

| Material handling | etc. |

Product Parameters

d=35mmD=52mm

B=1mm

More Choices

Company Profile

Quality Warranty

Granville as a manufacturer of high quality products, guarantees compliance with the highest standards relative to the use of the best steel quality in the production process, the highest standards in the design of contact surfaces, as well as the most efficient packing and lubrication of parts. From material coming, quality control through all processes. Except interal test, goods to third party inspection if required. After the center of inspection and experiment being founded, effective methods of inspecting all kinds of raw materials are mastered and then the reliability of bearings is ensured. One of our main objectives is the continued improvement in the quality of our products and processes, in pursuit of which we obtained ISO certification 9001:2008 and TS16949. Advantage Manufacturing Processes and Quality Control:01Heat Treatment02 Centerless Grinding Machine 11200 (most advanced)03 Automatic Production Lines for Raceway04 Automatic Production Lines for Raceway05 Ultrasonic Cleaning of Rings06 Automatic Assembly07 Ultrasonic Cleaning of Bearings08 Automatic Greasing, Seals Pressing09Measurement of Bearing Vibration (Acceleration)10 Measurement of Bearing Vibration (Speed)11 Laser Marking12 Automatic Packing